What happens when your lifting equipment breaks down 500 kilometres from the nearest town? Well, you’ll face delays, safety risks, and emergency repair bills that can exceed your budget.

The truth is, Australia’s remote sites present maintenance challenges with extreme distances, harsh weather conditions, and limited infrastructure support, unlike anywhere else in the world.

We’ve seen mining companies burn through budgets because they treated outback maintenance like suburban equipment servicing. At RUD Australia, we help mining operations build maintenance plans that prevent disasters.

In this article, we’ll show you:

- Remote site logistics and safety risks

- Data-driven maintenance that prevents failures

- Why specialised equipment needs expert support

- Building partnerships for complex repairs

Stick with us to learn remote maintenance challenges that could save your operation thousands.

The Unique Reality of Remote Site Maintenance

Remote site maintenance in Australia means dealing with distances that exceed most countries and conditions that break equipment faster than you can fix it. The combination of distance, weather, and infrastructure limitations creates challenges that standard maintenance approaches can’t handle.

Here’s what makes our outback operations so demanding:

The Logistical Challenges of the Outback

When your mining equipment breaks down 400 kilometres from civilisation, logistics become your most expensive problem. The reason is simple: every spare part and every tool needs to travel vast distances on roads that years of mining traffic have damaged beyond recognition.

For example, a hydraulic seal replacement that takes two hours in the city becomes a three-day ordeal involving charter flights and specialised transport. So what should be a quick fix becomes a major operation with costs that spiral out of control.

Our team has watched many mining engineering projects grind to a halt because one equipment failure triggered a cascade of logistical nightmares. It’s like watching dominoes fall, except each domino costs thousands of dollars.

Reducing Risks and Ensuring Safety

If mining equipment reliability fails in remote locations, safety risks grow dramatically because workers can’t evacuate quickly if something goes wrong. Your team ends up isolated with broken machinery, and productivity comes to a complete stop until help arrives.

Then, the mining industry makes it more complex because help is often hours away, and that leaves engineering professionals to handle emergencies with limited resources.

Also, when breakdowns happen, your people have to create makeshift solutions. That means improvising repairs with whatever materials are on site (which often creates more problems).

We recommend you build backup systems into every complete operation and keep direct contact with experienced mining industry support networks readily available.

Now that you understand these unique challenges, let’s look at how successful operations solve them.

An Integrated Engineering Management Program

If you’re thinking about remote maintenance as just fixing things when they break, then you’re only solving half the problem. It starts with building systems that catch issues before they become crane collapses, conveyor belt failures, or hydraulic system breakdowns. Your goal is to prevent these situations rather than scrambling to fix them.

Now follow these management programs to stay ahead of equipment failures:

Data-Driven Maintenance and Diagnostics

Instead of waiting for your equipment to tell you it’s broken, you should listen to what it’s saying while it’s still running. Once you start collecting the right data, patterns show you exactly when components need attention.

When engineering professionals working with safety professionals can spot important issues weeks before failure occurs, your maintenance team can plan repairs during scheduled downtime. The result is satisfying: you get fewer surprises and lower costs as you solve problems before they become emergencies.

Helpful Tip: Set up regular data collection schedules so your team can track trends over time. The patterns you see in the data often reveal problems weeks before they cause shutdowns.

Advanced Remote Technologies for Support

Condition monitoring is another part of a smart maintenance plan that delivers results. These services cover a wide range of monitoring solutions that the global industry relies on to test problems across various types of equipment.

Popular remote monitoring technologies include:

- Wireless sensors that track vibration patterns

- Thermal imaging cameras that detect overheating components

- Oil analysis systems that identify contamination early

- Load monitoring devices that prevent equipment overload

After you implement these monitoring systems, you can focus on the next step. You need to optimise how your complex equipment performs in harsh outback conditions.

Optimising Performance of Complex Equipment

Once your monitoring systems are tracking equipment health, the focus shifts from monitoring systems to maintaining the specialised machinery that keeps your operation running.

The thing is, remote mining sites rely on equipment that requires specialised knowledge because these machines handle extreme loads and operate in harsh conditions. That’s why standard maintenance crews often can’t handle the technical complexity when something goes wrong.

Let’s look at what makes equipment maintenance so challenging in remote locations:

Precision Maintenance for Specialised Machinery

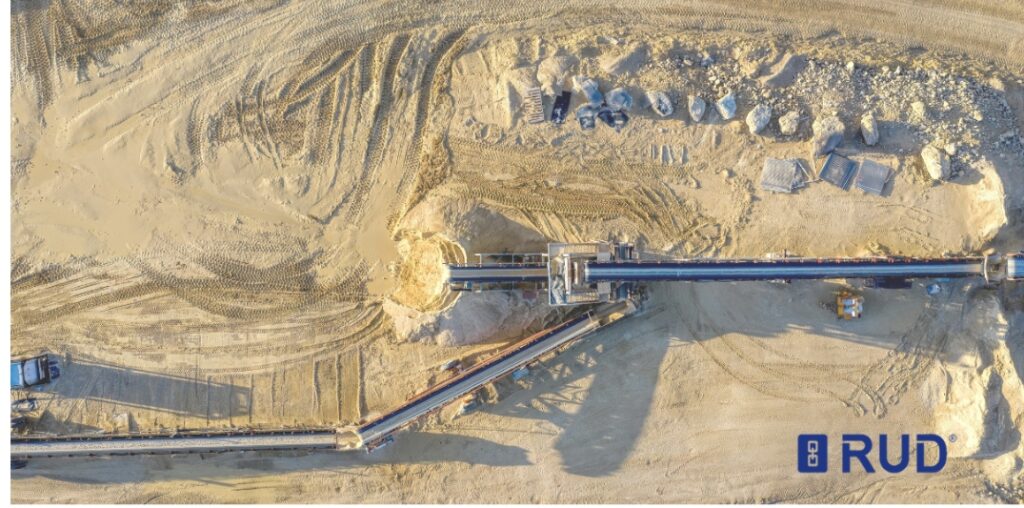

The mining industry uses complex and sophisticated equipment for all sorts of lifting jobs. For instance, overhead cranes with 100-tonne capacities, specialised winch systems for underground extraction, and multi-stage hydraulic platforms for heavy component installation.

If any of these systems break down, you’ll need technicians with a strong mechanical engineering background, especially with hydraulics. The reason is that hydraulic failures often involve multiple connected systems that require systematic diagnosis. When pressure drops or seals fail, your repair team needs to understand how each component affects the entire lifting system.

Building Expertise and Collaboration

How do you build the right expertise when you’re hundreds of kilometres from technical support? The answer lies in developing partnerships with specialists who understand your specific equipment needs.

What’s more, your maintenance team benefits from engineering management that connects them with design engineers who created the systems. This support network means your team can solve complex repair problems through remote consultation and detailed technical guidance. All you have to do is establish these connections before you need them.

In our experience, the mining operations that succeed long-term invest in ongoing training and maintain strong relationships with equipment manufacturers. These partnerships become lifelines when complex problems arise in remote locations.

Your Path Forward in Remote Equipment Management

It’s easy to feel overwhelmed by remote maintenance challenges because you’re dealing with vast distances, unpredictable weather, and limited local expertise. While Australia’s outback presents these challenges, there are solutions to keep your lifting equipment running reliably.

We’ve shown you how integrated management programs use data-driven diagnostics and remote monitoring to predict problems early. You’ve learned why specialised machinery requires precision maintenance and how building expert collaborations keeps complex equipment performing in harsh conditions.

Now you know the strategies that can help you get over those emergencies. Still, if you need any guidance putting these approaches into practice, our team will support you through every step of the process.